Developing a new polymer is challenging and needs to take into account what end applications are being catered to. Often, specific polymers will be identified for a certain application, but their limitations would be highlighted. Working off these limitations, a new material can be developed that seeks to fill gaps in performance. Selecting the best material is a critical step in the development of a polymer and this selection process will determine the quality of the final product. Strength, durability, malleability and many other factors are considered when a material is being selected and each of these factors holds a significant importance.

The development of PEEK, however, was surprising because suddenly, we had one polymer that exhibited properties at the far end of nearly every parameter. Whether we talk of tensile strength, strength-to-weight ratio, wear resistance, machinability or temperature resistance, PEEK truly checks all the boxes and leaves little doubt as to its effectiveness any time a debate on material selection is had.

Suffice to say, that the invention of PEEK revolutionized the plastic component manufacturing industry

PEEK was invented in the UK in 1978 and received a US patent in 1982. The processing conditions implemented to mould the material influence its crystallinity, or structure, and this results in the superb mechanical and chemical resistance properties of PEEK. PEEK is also highly resistant to degradation under high temperatures and resilient in organic and aqueous conditions. These properties make PEEK ideal for a wide array of components in diverse industries. Some of the major fields where this dynamic plastic material has been most effective are aerospace, the medical space, food & beverage and also the manufacture of PEEK plastic bearings.

PEEK in aerospace components

PEEK is optimal in aerospace due to its lightweight properties (it has a specific gravity that is half of aluminium), chemical inertness and toughness. Light-weight materials reduce the overall load of a vessel and, thus, reduce fuel costs and helps preserve the environment. Because PEEK is a chemically inert, the material is stable in extreme conditions and can withstand exposure to atmospheric particles. The fact that PEEK can be machined to the kind of close tolerances needed in aerospace make it an ideal material of choice.

PEEK in medical equipment

In the medical field, hygiene, durability and biocompatibility are all important factors when considering what materials to incorporate. PEEK offers flexible and durable properties and it also has no adverse effects on the skin or internal organs, which makes it an ideal material for implants. Biocompatible grades of PEEK can be used as sensor covers and transducers in medical equipment. Such grades ensure that even in the event of bodily contact, there would no adverse effects. Its resistance to extreme temperatures and low moisture absorption properties also make it a preferred choice for pumping mechanisms.

PEEK in food and beverages

The high-temperature resistance of PEEK makes it a favourable option in the production of powders and other ingredients in the food & beverage industry. PEEK is an effective alternative to PET and holds up well under the extreme temperatures for the drying of ingredients in food as well as feed for animals. The high wear resistance of PEEK also makes it an ideal choice for scrappers, where other polymers would either chip or deform. PEEK valves are also critical in coffee machines, where metallic valves have been known to impart an unfamiliar taste to the beverage. Since the last 5-10 years, high-end coffee machines around the world use PEEK valves in their equipment.

PEEK as a bearing material

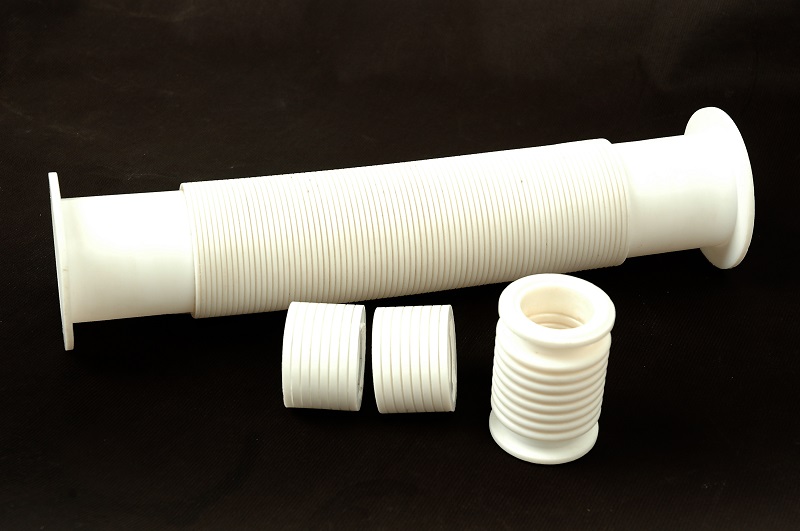

One field that has some of the most diverse applications of PEEK is the manufacturing PEEK bearings. PEEK makes an ideal material for bearings for many reasons. PEEK bearings can be made self-lubricating (usually with the addition of PTFE at a concentration of 15-25%). Abrasion causes microscopic bits to function as lubrication with inconsequential alteration to the bearings themselves. The durability and high-temperature resistance of PEEK bearings allows them to be thinner and lighter than traditional material bearings. Their light-weight characteristics make them more fuel-efficient and they don’t require the constant grease and maintenance that metallic bearings demand. As a result, PEEK can reduce bearing production and maintenance costs significantly. PEEK bearings can also run for long periods of time without freezing during operation. The low thermal expansion coefficient of PEEK ensures that it retains dimensional integrity over a very wide range of temperatures – both high and low. The chemical resistance of PEEK bearings allows them to withstand conditions that would otherwise cause damage to metal bearings. All these attributes make PEEK bearings an exceptional mechanical component for an endless number of products and functions

As we can see from these examples, PEEK is effective in a range of industries and PEEK bearings have become a favoured option as a mechanical component. PEEK bearings can be found in many different types of products and even in motors that go into the refrigerators and air conditioners in our homes. PEEK bearings will continue to be implemented in more and more products in the future as well. Keep your eyes open for PEEK plastic materials and PEEK bearings in the machines and products around you.